OK, I don't have any actual drawing-type plans but I'll measure

everything tomorrow and see what I can put together . I'll let you

know when I post it to the files section. Meanwhile, here's the

how-to part.

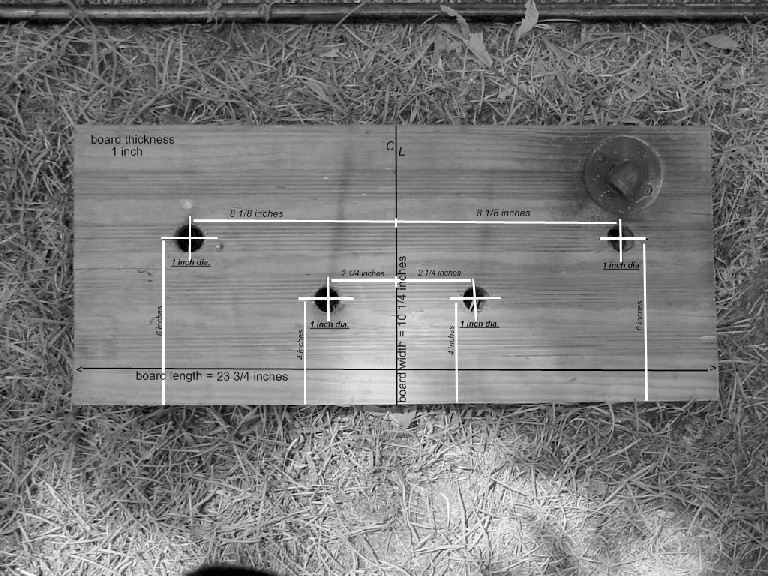

The wooden ends are from a 48" outdoor stair tread that I bought at

the local Lowe's store and cut in half making 2 - 24" sections. The

support rails are 4-60" pipes, 1/4" I.D. The original builder said

to use black iron pipe and I did, but I gotta tell you, that stuff

rusts like nobody's business. If I were doing it again, I'd use the

galvanized stuff. The pans are 14" dia. metal oil drain pans and are

scarce as hen's teeth around here. I first tried some 12" steel feed

pans and they were OK but didn't give much air flow room for my big

pots.......and I REALLY wanted the big pans anyway so I searched

through every auto parts store nearby and only found them at

O'Reily's (I didn't check NAPA). Unfortunately, each O'Reily's store

only stocks 1 pan at a time (though they will order them for you) so

I went to 3 stores in 2 cities to get them. They were worth the

trouble. The legs were my own addition. They are 48", 1/4 I.D.

pipes with caps on the bottoms to keep the dirt out and a "street-L"

to screw into on the top side. I'm not real sure just WHAT the name

of that round piece that the street-L is screwed into but you'll need

4 of them and 4 good wood screws to attach each one to the wood (16

screws total). You also need 8 more pipe end caps for the ends of

the support rails.

Now then, in my opinion, I wanted the bottom support rails about

1/3 of the way in from each side, If the bottom was 12", and I think

it was, I wanted the centers of the holes to be 2" on either side of

the center of the end piece when measured longways. I measured the

height of the pans top to bottom and decided how high up the sides I

wanted my upper support poles and centered about 7 1/4" each side of

the center line. Actually, I used the 4 divisions on the wooden end

piece that you can see in one of the photos for the heights and it

seemed just fine. At this time I wasn't really planning any legs yet.

The holes need to be bigger than the outside diameter of the pipes

but smaller than the outside diameter of the caps. This keeps the

pipes from sliding out when you don't want them to. Think about

that. Not pretty. Anyway, unless you're a very accurate woodworker

(I'm not) give your pipes a little wiggle room because the two sets

of holes will probably not match up perfectly. Put the caps on one

end of each support pole (pipe wrenches, small) and slide the poles

through the holes in both end pieces. Sometimes it is easier to

slide them through the first one, stand the thing on its end with the

pipes sticking up and work the second end piece down over the pipes.

It will get easier with use. Put the caps on the other ends and lay

your table top down. The pans should fit in easily.

Now for the legs. Warning, this is going to be frustrating. Figure

out how high you want your table to be and fid a way to support it at

about that height. I used two sawhorses. That's also how I figured

out the height, however tall those two sawhorses made it. Now take

the street-L and screw it into the center hole of the leg-base

(whatever the name is) tighten it in as tight as humanly possible

with the wrenches because it has a tendency to shift. Do this for

each leg. Now put a cap tightly on one end of each leg and screw the

other end into the street-L. Hand tight will do here. OK, the leg-base

whatcha-ma-callits go in the upper righthand corner of the end

pieces. Start with the inside corners and thread the leg over the

outside and under the inside support pole on the right hand side.

Make it tight against the inside bar with the end pushing hard

against the ground. Now put in the wood screws, at least two, the

others can be added later. Keep the table level. Do the other

inside leg exactly the same with the base in ITS upper right corner,

threaded the same way. Check the photos to clarify. You might want

to print some out. Once the inside legs are attached, go to one end

and pull the upper and lower right hand support poles towards you

about 3". Now install the outer leg threading it the same way you did

the inner ones. Now do the other end the same way. I think you're

finished now. leave the lower support poles sticking out just enough

to brace the legs, or you could just use slightly longer poles I

guess. If you used the black iron, go ahead and get some high-temp

grill paint and paint all the iron or it will soon rust away.